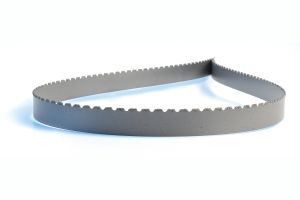

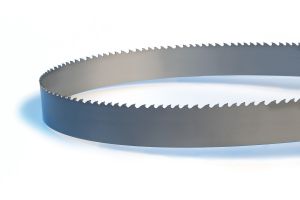

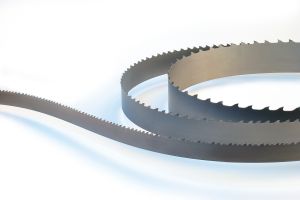

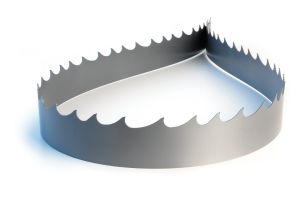

LENOX Carbide Band Saw Blades

LENOX carbide band saw blades are designed to cut composites, metal and wood. High performance materials are optimized so these band saw blades cut faster and last longer than any other blades available.

Hastings Saws builds custom LENOX band saw blades to your specification with guaranteed welds. FREE SHIPPING on orders $75+.