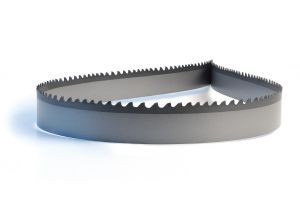

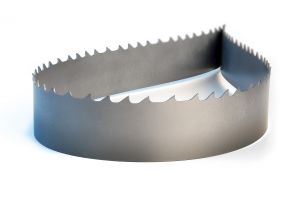

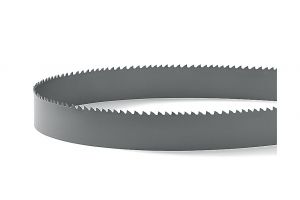

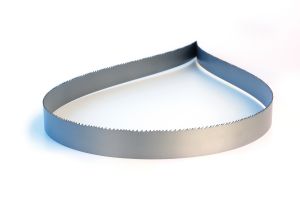

LENOX Bi-metal Band Saw Blades

LENOX bi-metal band saw blades are the highest performing and most cost effective solution for metal sawing applications. High speed steel tooth tips combined with flexible alloy steel backing material in a wide variety of blades ensure optimal performance and durability.

Hastings Saws builds custom LENOX band saw blades to your specification with guaranteed welds. FREE SHIPPING on orders $75+.